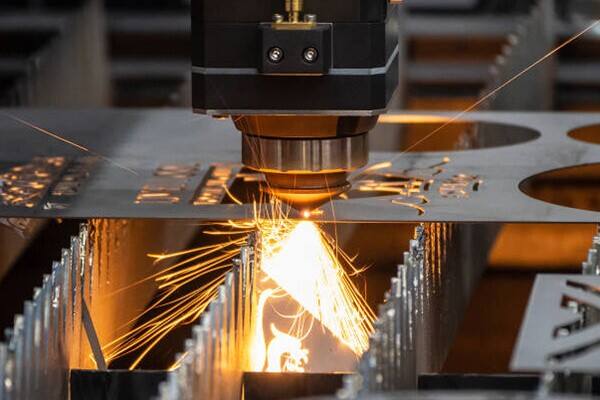

Laser cutting is a manufacturing process where a laser beam pierces raw sheet stock to produce flat geometries. A range of metals are available, which work well for components such as washers, mounts, brackets, and housings.

Laser cutting is commonly used for:

-- prototyping designs or testing product requirements

-- efficiencies of scale up to 50+ parts

-- parts with standard connectivity features (USB, HDMI, ethernet ports)

Follow these guidelines for flat, laser cut parts to ensure quality and accelerate production time.

| Maximum Size | Thickness 0.134 - 0.250 in.: 39 in. x 19 in. . |

| Thickness 0.024 in - 0.134 in.: 39 in. x 47 in. | |

| Minimum Part Size | 0.25in.x0.25in. |

| Material Thicknesses | 0.024in.-0.250in. |

| Tolerances | +/- 0.005 in. for all features (except for hardware holes) . |

| +0.003/-0.000 in. on hardware insert holes to ensure correct seating of inserts. |

We offer the following metal materials for custom laser cut parts. Note that based on material thickness, maximum part size will vary.

| Material | Grade | Thickness Available |

| Aluminium | • 5052-H32 | 0.025 in. - 0.250 in. (0.635mm - 6.35mm) |

| • 6061-T6 | ||

| Steel | • CRS/HRPO | 0.025 in. - 0.250 in. (0.635mm - 6.35mm) |

| • Galvanneal | ||

| • Galvanized | ||

| Stainless Steel | • 304-2B | 0.025 in. - 0.250 in. (0.635mm - 6.35mm) |

| • 304 #4 | ||

| • 316-2B | ||

| Copper | • C1010 | 0.025 in - 0.125 in. (0.635mm - 3.175) |

| • C1100 | ||

| Brass | • C260 | 0.025 in. - 0.125 in. (0.635mm - 3.175) |

Laser cutting is a frequently used manufacturing process in industries such as energy storage, computer electronics, robotics, and aerospace. Common parts fabricated with laser cutting include:flat patterns, face plates, washers, mounting plates and panels.