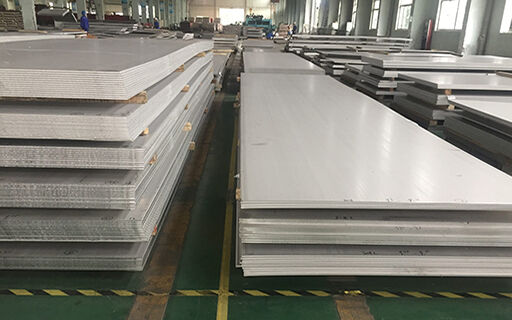

To ensure rapid delivery to our customers, our warehouse consistently stocks over 70 types of commonly used raw materials, including carbon steel, stainless steel, aluminum alloy, copper, and more, with material thicknesses ranging from 0.1mm to 35mm. All raw materials are sourced from China's top five steel manufacturers and comply with material inspection standards in both North America and the European Union.

Precision Laser Cutting and Automated Efficiency: Our company has three precision laser cutting machines. Utilizing our advanced CNC-controlled equipment, we deliver accurate and consistent cuts on various metal sheets. The combination of our unique expertise and automation allows us to enhance efficiency while maintaining impeccable quality standards. Our automation capabilities not only boost productivity and shorten lead times but also eliminate mold costs, thereby giving your products a significant competitive edge.

At our company, we take pride in our commitment to quality and sustainability. Our bending and forming services are carried out using the most advanced electric bending machines. These machines not only run fast, have low production costs, no mold cost, but also save energy.

Our electric bending machines provide excellent control and precision, allowing us to easily handle various complex bending and forming tasks.Our advanced equipment and experienced team ensure that your products are completed to the highest quality and precision standards.

Our company has 5 manual welding machines and 2 robot welding machines. We can provide customers with various welding services, including metal arc welding, MIG/MAG welding, TIG welding, laser welding, and friction welding. ... wait. Each type of welding has unique advantages that ensure the best results for your specific project requirements. Please send us detailed requirements for the welding products you need so that our engineers can provide you with the most reasonable welding service.

MIG Welding: Also known as Gas Metal Arc Welding (GMAW), MIG welding is a versatile solution renowned for its speed and adaptability. It is an excellent choice for both thick and thin materials, making it highly suitable for large production runs where efficiency and speed are critical.

TIG Welding: TIG (Tungsten Inert Gas) Welding, or Gas Tungsten Arc Welding (GTAW), is known for producing high-quality, clean welds. This method offers exceptional control, making it ideal for complex or delicate welding tasks, and is perfectly suited for projects that require precision and attention to detail.

Laser Welding: Laser welding is at the forefront of welding technology. It provides unparalleled precision, minimal thermal distortion, and highly controlled energy input. This method is ideal for high-speed, automated welding processes, particularly for thin materials and intricate work.

We are committed to providing customers with comprehensive precision machining solutions, covering various advanced processes such as CNC lathes, CNC milling machines, and CNC machining centers. With an experienced team of engineers, we are able to provide customers with professional material processing guidance and technical support, ensuring precise and controllable every step from drawings to finished products.

Whether it's small-scale trial production of complex components or large-scale production needs, please trust that we can provide precise and high-quality services for each of your products.

We can provide customers with products made of various materials, including carbon steel, stainless steel, aluminum alloy, and copper/brass...etc.

If the material is carbon steel, surface treatment can be rust proof oil, cold galvanizing, hot-dip galvanizing, chrome plating, electroplated gold plating, electroplated nickel plating, powder coating of various colors, painting of various colors, E-coated;

If the material is stainless steel 201/301/304/304L/316/316L, surface treatment can be bare, deburred, sandblasting, vibration polishing, electropolishing, brush polishing, mirror polishing, magnetic polishing, powder coating of various colors, painting of various colors, PVD coating;

If the material is aluminum alloy, surface treatment can be bare, deburred, sandblasted, brushed polished, anodized of various colors, powder coating of various colors, and painting of various colors;

If the material is copper/brass, surface treatment can be bare, deburred, and polished.

As a professional manufacturer of sheet metal fabrication parts, we fully recognize packaging’s decisive role in ensuring product safety during international transportation. Drawing on years of cross-border supply experience, we’ve developed a Standard Export Packaging system integrating multi-layer protection, compliant design, and flexible customization—guaranteeing intact delivery and efficient customs clearance of every batch.

All core packaging solutions meet international standards and target market import regulations, balancing protection and cost-effectiveness: custom-sized high-weight corrugated cartons with shockproof buffers (pearl cotton, bubble film, etc.) and moisture-proof treatment; fumigation-free plywood, waterproof plastic, and ultra-high-load steel pallets; fully enclosed reinforced plywood boxes for precision/large parts.

We offer customized services: anti-static/rust-proof materials, detachable/modular structures, and logo printing. Our team tailors optimal plans based on product attributes and market requirements.

All packaging undergoes strict load, drop, and moisture-proof tests, using high-quality eco-friendly materials. Professional supervision throughout ensures safe global delivery.